PBPL Photoinjector

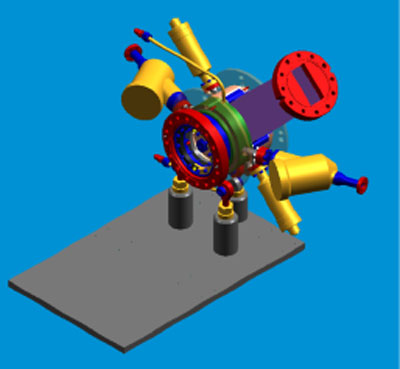

The 1.6 cell S-band RF gun is one of the most highly successful innovations in RF technology associated with the PBPL and its collaborating institutions. This device is the enabling technology of most of the high brightness, picosecond beam laboratories world-wide. Originally developed at BNL, and then put in its commonly used form by a BNL/SLAC/UCLA collaboration, versions of this device have been built wholly or partially at UCLA for BNL ATF, Univ. of Maryland, Livermore PLEIADES lab, SLAC GTF, UCLA Neptune Lab (2 versions), and SLAC ORION. The most recent generation of 1.6 cell S-band RF gun developed in collaboration with the SLAC ARDB group for the ORION project (shown at left) is also the basis for the RF gun at the SPARC photoinjector. This version of the gun was processed up to 15 MW of power, or over 150 MV/m on-axis fields. The RF power waveguide, visible on the upper right, is coupled to the full cell, and vacuum is pumped through a symmetrizing port. Also symmetrically placed in the full cell are the two tuners, at 90 degrees with respect to the waveguide (the upper one is visible), and the entrance and exit laser ports, half way between waveguide and the vacuum ports. The beam exit port is on the front of the picture. The symmetry of the structure determines that of the electromagnetic field distribution, and it is important to avoid dipolar excitation components; the lowest perturbation of the RF mode is limited to quadrupole, with negligible effect on the beam dynamics.

The photocathode insert is centered on the wall of the flange that terminates the half-cell. Cathodes such as single-crystal Cu and Mg have been used to obtain high quantum efficiency in this device. Metal photocathodes demand very good vacuum, at the level of 10-8 Torr during high gradient operation, which typically implies that the vacuum without RF be one order of magnitude better in the absence of rf power. These demands are met by stringent control of the gun manufacturing process, and by implementing as much pumping on the gun as possible: through the direct pumping port, through the waveguide, at the beam port, and behind the cathode plate through an array of small pumping holes. In addition, one often cleans cathode materials with the laser in situ, a process a technique pioneered at BNL.

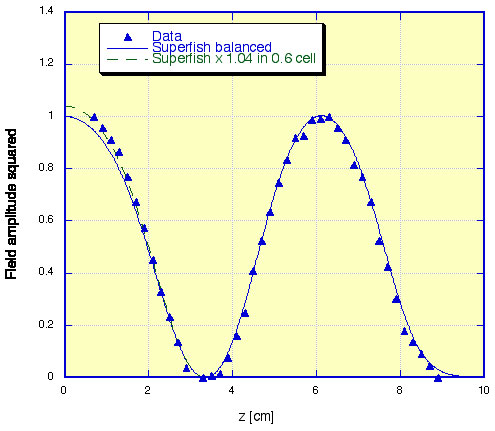

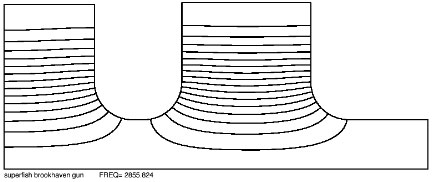

The process used in producing the 1.6 cell gun, as well as many of other RF devices at UCLA, entails machining and all RF testing will be performed at UCLA, while the brazing is to be undertaken at SLAC. PBPL has network analyzers and related RF testing facilities that have been built up for RF cavity production. These testing facilities allow such techniques such as mode tuning and field balancing (using bead pull methods). Measurements at PBPL are complemented by design and modeling programs such as SUPERFISH, HFSS, and GdfidL.